Welcome to your heat press instruction manual. This guide provides essential information on safe operation, setup, and maintenance to ensure optimal performance and creative success.

Purpose and Scope of the Manual

The purpose of this manual is to provide clear instructions and safety guidelines for the heat press, ensuring safe and effective use. Its scope covers setup, operation, and maintenance, offering comprehensive guidance for optimal performance and troubleshooting common issues. This guide is designed to assist both novice and experienced users in understanding and utilizing the heat press machine to its full potential, ensuring successful and creative outcomes while maintaining safety standards.

Important Safety Precautions

Always follow safety guidelines when operating the heat press. Ensure the machine is placed on a stable, heat-resistant surface, away from flammable materials. Keep children and pets away from the press while in use. Avoid touching heated surfaces, and wear protective gloves when handling materials. Never leave the press unattended during operation. Properly ventilate the workspace to prevent inhaling fumes from materials. Follow the manufacturer’s temperature and pressure settings to avoid damage or injury. Regularly inspect the machine for wear and tear, and unplug it when not in use to ensure safe operation and longevity of the equipment.

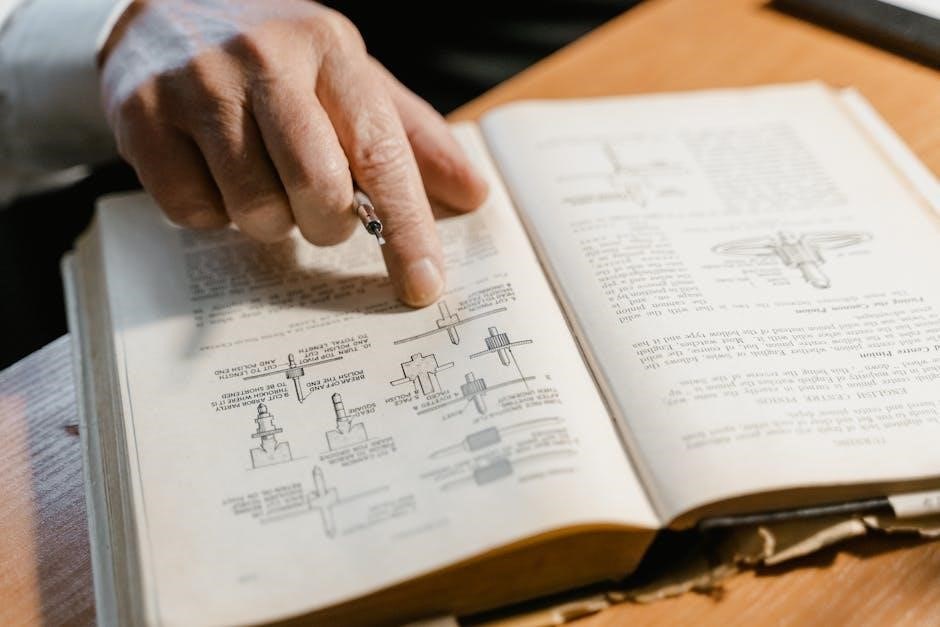

Overview of Heat Press Components

Your heat press consists of several key components. The heating plate is the core element, providing consistent heat distribution. The pressure adjustment knob ensures even force application. A digital control panel allows precise temperature and timer settings. The press bed is durable and designed for easy material placement. Additional attachments, such as mug and hat presses, expand functionality. The machine’s frame is built for stability, and safety features include automatic shut-off and heat-resistant insulation. Understanding each part ensures proper use and maintenance, optimizing your heat pressing experience for various projects and materials.

Setting Up Your Heat Press

Unbox and inspect your heat press, ensuring all components are included. Place it on a stable, heat-resistant surface, allowing adequate space for operation and attachment storage.

Unboxing and Initial Inspection

Carefully unbox your heat press machine and verify all components are included, such as the press, attachments, and user manual. Inspect for any visible damage or defects. Ensure the machine is placed on a firm, level surface away from flammable materials. Check that all electrical connections are secure and meet local safety standards. Familiarize yourself with the control panel and settings before proceeding. This step ensures safe and proper operation, preventing potential issues during use. Proper inspection guarantees your heat press is ready for assembly and configuration.

Choosing the Right Location for the Heat Press

Select a stable, level surface for your heat press, ensuring it can support the machine’s weight. The area should be well-ventilated, away from flammable materials and direct sunlight. Ensure ample space around the press for easy access and operation. Keep the machine away from children and pets for safety. Avoid placing it near water sources or humid environments to prevent damage. Ensure proximity to a grounded electrical outlet, adhering to the machine’s power requirements. Proper placement enhances safety, functionality, and convenience, ensuring optimal performance and longevity of your heat press.

Assembly and Initial Configuration

Begin by carefully unpacking your heat press and checking all components for damage. Follow the manual to attach any additional accessories, such as the heat press plate or hat press. Place the machine on a stable surface and plug it into a grounded electrical outlet. Turn on the power and allow the press to heat up to its default temperature. Refer to the manual for specific assembly steps, as models may vary. Once assembled, perform a test run without materials to ensure proper function. Adjust settings as needed and familiarize yourself with the controls before starting your first project. Always follow safety guidelines.

Operating the Heat Press

Learn to operate your heat press by adjusting temperature and pressure settings, preparing materials, setting the timer, and initiating the pressing process safely and efficiently.

Adjusting Temperature and Pressure Settings

Adjusting the temperature and pressure settings on your heat press is crucial for achieving optimal results. Start by setting the target temperature based on the material you are working with, typically between 260°F and 400°F for most transfers. Use the +/- buttons to adjust the temperature precisely. Once set, press the “SET” button to confirm. For pressure, ensure it is evenly distributed to avoid uneven transfers. Different materials, such as cotton, polyester, or ceramics, require specific pressure and temperature settings. Always refer to the manufacturer’s guidelines for recommended settings. Proper calibration ensures a professional finish and prevents damage to your press or materials.

Setting the Timer and Starting the Press

To set the timer, use the +/- buttons to select the desired pressing time based on your material and transfer type. Once the timer is set, press the “START” button to begin the heating cycle. The press will automatically start when the set temperature is reached. Ensure the timer is accurately set to avoid over-heating or under-heating the material. For most transfers, a pressing time of 3-5 minutes is standard. Always monitor the timer to ensure the process completes successfully. Proper timing is essential for achieving a durable and professional finish. Refer to the manual for specific time recommendations for different materials.

Preparing Materials for Pressing

Before pressing, ensure materials are clean and dry. For fabrics, pre-wash and dry to remove finishes that may interfere with transfers. Sublimation and heat transfer vinyls require proper cutting and weeding. Place materials on the press bed, aligning designs carefully. Use a heat-resistant tape to secure items if necessary. Avoid overcrowding the press bed to ensure even heat distribution. Always refer to the manual for material-specific temperature and time settings. Proper preparation ensures a professional finish and prevents damage to your press or materials. Ensure all elements are centered and smoothed out before closing the press for optimal results.

Safety Guidelines and Maintenance

Always keep the heat press in a well-ventilated, clear area; Avoid overheating and never leave the press unattended. Regularly clean and inspect components for wear. Follow manual guidelines to ensure longevity and safety.

Regular Maintenance Tasks

Regular maintenance ensures your heat press operates efficiently and safely. Clean the heating plate and pressure pad with a soft cloth after each use. Lubricate moving parts periodically to prevent wear. Check and replace worn-out components like the heating element or thermostat. Store the press in a cool, dry place when not in use. Always follow the manufacturer’s maintenance schedule for optimal performance and longevity. Proper care extends the lifespan of your heat press and ensures consistent results in your projects. Regular inspections and timely repairs prevent unexpected downtime and maintain the quality of your work.

Troubleshooting Common Issues

Identify and resolve issues promptly to maintain your heat press’s performance. If the machine isn’t heating, check the power cord and thermostat. For uneven pressure, adjust the pressure pad or ensure even material placement. If transfers aren’t adhering, verify temperature and time settings. Refer to the manual for specific error codes and solutions. Regular maintenance can prevent many issues. Always unplug the press before troubleshooting to ensure safety. Keep the user manual handy for quick reference. Addressing problems early avoids costly repairs and keeps your projects on track. Troubleshooting common issues ensures smooth operation and professional results every time.

Advanced Techniques and Tips

Master advanced techniques to elevate your heat press projects. Experiment with multi-layer designs, unique materials, and precise temperature control for professional results and creative freedom.

Optimizing Heat Press Performance

Maximize your heat press’s efficiency by ensuring proper calibration of temperature and pressure settings. Regularly clean the heating plate to prevent residue buildup and maintain even heat distribution. Preheat the press before use to achieve consistent results. For materials like vinyl, adjust pressure based on thickness, and for delicate fabrics, reduce temperature slightly. Keep the press on a stable, heat-resistant surface to prevent damage. Additionally, use a timer accurately to avoid overexposure, which can damage materials. Proper maintenance and adherence to guidelines ensure longevity and optimal performance of your heat press, delivering professional-grade results every time.

Working with Different Materials and Designs

Expand your creative possibilities by working with various materials and designs. Start with common substrates like cotton, polyester, and blends, ensuring compatibility with heat transfer techniques. Experiment with sublimation on ceramics or glass for vibrant, durable finishes. Use heat transfer vinyl for custom designs on fabrics, and explore flock or foil transfers for unique textures. Adjust temperature and pressure settings based on material thickness and sensitivity. Practice on scrap materials to perfect your technique before final application. This versatility allows you to create personalized items like t-shirts, mugs, and phone cases, making your heat press a valuable tool for diverse projects and crafts.