Sliding gate guide rollers are essential components that ensure smooth, quiet, and efficient gate operation. They maintain alignment, distribute load evenly, and reduce friction.

Overview of Sliding Gate Guide Rollers

Sliding gate guide rollers are critical components designed to facilitate smooth and quiet gate operation. They are available in various materials like nylon, steel, and hybrid polymers, offering durability and low friction. Guide rollers support the gate’s weight, maintain alignment, and ensure consistent movement along the track. They are particularly useful for arched or uniquely designed gates, where traditional top guides may not fit. Guide rollers come in different lengths, offsets, and configurations, making them versatile for residential, commercial, or custom installations.

Importance of Guide Rollers in Sliding Gates

Guide rollers are crucial for smooth gate operation by reducing friction and preventing wear. They ensure proper alignment, distribute weight evenly, and enhance safety. Proper installation and maintenance are vital for optimal performance and longevity.

Types of Sliding Gate Guide Rollers

Guide rollers come in nylon, steel, and adjustable dual varieties, each offering unique benefits for durability, load capacity, and flexibility in gate systems.

Nylon Guide Rollers

Nylon guide rollers are durable and long-lasting, offering smooth operation and minimal noise. They are resistant to wear and tear, making them ideal for light-duty applications. Their versatility allows them to function well in various environmental conditions, including moisture and temperature fluctuations. Nylon rollers are also low-maintenance and provide consistent performance over time, making them a popular choice for sliding gates.

Steel Guide Rollers

Steel guide rollers are highly durable and ideal for heavy-duty sliding gates. Made from robust materials like stainless or galvanized steel, they offer exceptional strength and resistance to corrosion. Their sturdy construction ensures smooth operation and long-lasting performance, making them a reliable choice for commercial and industrial applications where weight and stress are significant.

Adjustable Dual Roller Guides

Adjustable dual roller guides offer flexibility and precision for sliding gates. These systems feature two rollers that can be fine-tuned to ensure proper alignment and smooth operation. Ideal for heavy-duty gates, they often include durable materials like steel or nylon. Their adjustability minimizes wear and tear, ensuring consistent performance over time, especially in large or industrial applications.

Materials and Durability

High-quality materials ensure durability and performance in sliding gate guide rollers, with options like steel, nylon, and polymer offering resistance to wear and environmental factors for reliable operation.

Self-Lubricating UHMW Plastic Rollers

Self-lubricating UHMW plastic rollers are renowned for their durability and low-friction performance. Made from ultra-high molecular weight polyethylene, they offer exceptional resistance to wear, moisture, and temperature fluctuations. Their self-lubricating properties minimize maintenance, ensuring smooth gate operation and reducing noise. These rollers are ideal for heavy-duty applications, providing long-lasting reliability in various environmental conditions.

Hybrid Polymer Track Rollers

Hybrid polymer track rollers combine the strength of metal with the durability of polymer materials. Designed for heavy-duty applications, they offer superior load capacity and resistance to wear. These rollers are highly resistant to chemicals and extreme temperatures, making them ideal for harsh environments. Their low-maintenance design ensures smooth operation and minimal noise, perfect for large or industrial sliding gates.

Heavy-Duty Metal Rollers

Heavy-duty metal rollers are constructed from robust materials like steel, offering exceptional strength and durability. They are ideally suited for industrial and commercial sliding gates, providing exceptional load-bearing capacity. These rollers require regular lubrication to prevent rust and ensure smooth operation, making them a reliable choice for heavy-duty applications where longevity and reliability are paramount.

Sizes and Offsets

Sliding gate guide rollers come in various sizes and offsets to accommodate different gate setups, ensuring proper alignment and smooth operation. Correct sizing is crucial for functionality.

Common Lengths and Offsets

Sliding gate guide rollers are available in standard lengths, typically ranging from 6 to 12 inches, to suit various gate sizes. Offsets, measuring the distance from the gate to the roller, usually range from 1 to 3 inches. Proper alignment ensures smooth operation, while custom lengths and offsets can be tailored for specific setups. Always check manufacturer specifications for compatibility with your gate system.

Individual Rollers vs. Assembly Kits

Individual rollers offer flexibility for specific replacements or unique setups, allowing customization. Assembly kits provide convenience, containing pre-packaged rollers and hardware for seamless installation. Kits ensure compatibility and consistency, ideal for new installations or comprehensive upgrades. Choose individual rollers for targeted repairs and kits for efficiency and ease in larger projects.

Installation and Alignment

Proper alignment ensures smooth operation and longevity. Use a level and drill for accurate setup. Misalignment can cause wear and tear, so precision is key.

Tools and Materials Needed

Drill, level, wrench, screwdriver, and measuring tape are essential. Screws, bolts, washers, and brackets are required for mounting. Lubricant and cleaning supplies help maintain smooth operation. Ensure all components are compatible with your gate system for a secure and durable setup. Proper tools prevent installation errors and ensure alignment accuracy.

Step-by-Step Installation Process

Install guide rollers by first preparing the gate and track. Attach mounting brackets to the gate frame, then secure rollers to these brackets. Ensure proper alignment with the track system. Tighten all fasteners firmly to prevent movement. Finally, test the gate’s operation by sliding it open and close to ensure smooth, consistent motion without obstructions or misalignment.

Common Mistakes to Avoid

Common mistakes include improper alignment of rollers with the track, leading to gate misalignment. Over-tightening can cause undue stress, while under-tightening results in loose movement. Using incorrect roller sizes or materials for the gate’s weight can cause premature wear. Neglecting to lubricate moving parts and ignoring manufacturer instructions can also lead to poor performance and reduced longevity of the system.

Maintenance and Repair

Regular lubrication and cleaning prevent friction and wear. Inspect rollers for damage, replace worn ones promptly to ensure smooth gate operation and longevity.

Cleaning and Lubrication

Regular cleaning of guide rollers removes dirt and debris, ensuring smooth operation. Use a cloth or brush to wipe away grime. Apply silicone-based lubricants or grease to moving parts to reduce friction and prevent wear. Lubricate every 3-6 months or after exposure to harsh weather. Proper maintenance extends the lifespan of rollers and keeps gates functioning quietly and efficiently.

Replacing Worn-Out Rollers

Replace worn-out rollers promptly to maintain smooth gate operation. Inspect for visible wear, cracks, or flat spots. Use a wrench to remove old rollers, then install new ones securely. Ensure proper alignment with the track to prevent misalignment. Apply lubricant after installation for optimal performance. Regular replacement prevents further damage and ensures consistent gate functionality over time.

Adjusting Misaligned Rollers

Adjust misaligned rollers to ensure smooth gate operation. Loosen the mounting bolts slightly, then realign the roller with the track. Use a spirit level to verify proper alignment. Tighten the bolts firmly once aligned. Regular inspections and minor adjustments can prevent major issues. Proper alignment reduces friction and extends the lifespan of both rollers and the gate system.

Troubleshooting Common Issues

Identify and resolve common issues like noise, misalignment, or excessive friction. Regular lubrication, alignment checks, and inspections help maintain optimal performance and prevent premature wear.

Noise Reduction Tips

Minimize sliding gate noise by ensuring proper roller alignment and lubrication. Regularly clean debris from tracks and rollers. Replace worn-out rollers and tighten loose components. Use noise-dampening materials like rubber pads or silicone sprays on moving parts. Check for misalignment and adjust rollers to fit the track perfectly. Lubricate hinges and rollers periodically to reduce friction and squeaking sounds. Ensure the gate isn’t overloaded, as excess weight can cause strain and noise. Consider upgrading to quieter nylon or polymer rollers if metal ones are too noisy. Proper maintenance and timely replacements are key to a smooth, quiet operation.

Fixing Gate Misalignment

Correcting a misaligned sliding gate involves inspecting and adjusting the guide rollers. Ensure the rollers are properly seated in their tracks and free from obstructions. Check for wear or damage and replace them if necessary. Adjust the roller alignment to align with the track, ensuring smooth gate movement. Lubricate rollers to reduce friction and realign the gate. Tighten any loose hinges or brackets that may contribute to misalignment. If issues persist, consider consulting a professional for precise adjustments or repairs.

Addressing Friction Problems

Friction issues in sliding gates often arise from dirty or clogged rollers, lack of lubrication, or misalignment. To address this, clean the rollers thoroughly and apply a silicone-based lubricant. Regular maintenance, including inspecting for debris and ensuring proper alignment, can prevent friction issues. Using high-quality lubricants and keeping the track system clean also helps maintain smooth gate operation.

Accessories and Additional Components

Accessories like mounting hardware and V-track systems ensure proper alignment and smooth operation of sliding gate guide rollers, while brackets and lubricants enhance durability and functionality.

Brackets and Mounting Hardware

Brackets and mounting hardware are essential for securing guide rollers to the gate frame or post. They come in various types, including fixed and adjustable options, to accommodate different gate designs. Made from durable materials like steel or aluminum, these components ensure proper alignment and stability. High-quality bolts and screws are often included for secure installation, preventing movement or wear over time.

Track and V-Track Systems

Track and V-track systems provide a smooth surface for guide rollers to glide on, ensuring efficient gate movement. Made from durable materials like steel or aluminum, these tracks are designed to withstand heavy use. V-tracks are particularly useful for hanging gates, offering stability and reducing wear. Proper alignment and installation of these systems are crucial for optimal gate performance and longevity.

Lubricants and Greases

Lubricants and greases are essential for maintaining smooth operation of sliding gate guide rollers. Silicone-based sprays or lithium-based greases are commonly used to reduce friction and wear. Regular application ensures quiet movement and prevents corrosion. Over-lubrication should be avoided to prevent dirt accumulation. Proper lubrication extends the lifespan of rollers and ensures optimal gate functionality, making it a critical maintenance step.

Applications and Compatibility

Sliding gate guide rollers are suitable for residential, commercial, and industrial gates, ensuring smooth operation across various gate types, including metal, wood, and vinyl designs, offering compatibility with different load capacities and environments.

Residential Sliding Gates

Residential sliding gates benefit from guide rollers due to their quiet operation and durability. They are ideal for homeowners seeking smooth, low-maintenance gate systems. Available in various materials like nylon or polymer, these rollers minimize noise and wear, ensuring years of reliable performance in residential settings. Easy to install and maintain, they enhance the functionality and longevity of sliding gates in home environments.

Commercial and Industrial Gates

Commercial and industrial sliding gates require robust guide rollers to handle heavy use and large gate systems. Durable materials like heavy-duty steel or hybrid polymers ensure long-lasting performance. These rollers are designed to support significant weight and withstand harsh environments, making them ideal for warehouses, factories, and industrial facilities. They provide smooth operation and minimize wear, ensuring reliable functionality in demanding settings.

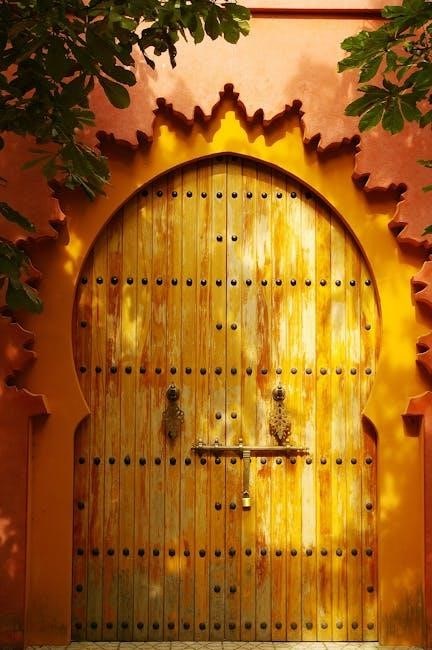

Architectural and Custom Designs

In architectural and custom designs, sliding gate guide rollers are often used to create sleek, modern aesthetics while maintaining functionality. They can be integrated invisibly into the gate’s design, preserving the visual appeal. Customizable materials and sizes allow for tailored solutions, ensuring compatibility with unique gate styles. This makes them ideal for high-end residential, luxury, or bespoke applications where both form and function are prioritized.

DIY vs. Professional Installation

DIY installation saves money but demands proper skills and tools. Professional installation ensures expertise, reliability, and warranty, making it ideal for complex setups and long-term durability.

Pros and Cons of DIY Installation

DIY installation offers cost savings and the satisfaction of completing the project yourself. However, it requires proper tools, skills, and time. Improper installation can lead to misalignment or safety hazards. While feasible for small gates, larger or complex systems may demand professional expertise to ensure reliability and longevity.

When to Hire a Professional

Hire a professional for complex installations, large gates, or heavy systems requiring precise alignment. Professionals ensure safety, proper load-bearing capacity, and compliance with regulations. They handle unexpected issues and provide warranties. DIY may save money, but professionals guarantee reliability, especially for high-traffic or custom designs, avoiding costly future repairs and ensuring optimal performance.

Case Studies and Real-World Examples

Successful installations highlight smooth operation, reduced wear, and minimal maintenance. Customizable guide rollers meet specific client needs, ensuring durability and efficiency across residential and commercial applications.

Successful Gate Roller Installations

Real-world examples demonstrate the effectiveness of guide rollers in ensuring smooth gate operation. Residential estates and commercial facilities report reduced noise and extended gate lifespan. Nylon rollers excel in coastal areas for corrosion resistance, while steel rollers provide durability in heavy-duty applications. Proper alignment and material selection are key to these successes, enhancing overall functionality and user satisfaction.

Lessons Learned from Failures

Failures in sliding gate systems often stem from improper alignment or inadequate material selection. Misaligned rollers can cause gates to jam or wear unevenly. Using rollers unsuitable for environmental conditions, like nylon in high-temperature settings, accelerates degradation. Regular maintenance, such as lubrication, is crucial to prevent friction-related issues. These insights highlight the importance of precise installation and material compatibility for long-term reliability.

Future Trends in Sliding Gate Technology

Advancements in smart automation, energy-efficient designs, and sustainable materials are reshaping sliding gate systems, offering enhanced security, durability, and user convenience for modern applications.

Advancements in Materials

Future trends include the development of eco-friendly, high-performance materials like advanced composites and graphene-infused polymers, offering superior durability, reduced noise, and enhanced weather resistance for guide rollers, ensuring smoother gate operation and longer lifespan.

Smart and Automated Systems

Next-generation sliding gates feature smart automation, integrating sensors, motorized systems, and IoT connectivity for seamless operation. Automated open/close functionality, obstacle detection, and energy-efficient designs enhance convenience and safety. These systems also support remote monitoring and voice command compatibility, aligning with modern smart home technologies for a futuristic, user-friendly experience that boosts property security and accessibility.

Sliding gate guide rollers are essential for smooth operation, ensuring durability and safety. Proper maintenance and selection enhance performance, making them a vital component for reliable gate functionality.

Final Thoughts on Sliding Gate Guide Rollers

Sliding gate guide rollers are a critical component for ensuring smooth, quiet, and efficient gate operation. Proper installation, maintenance, and selection of rollers significantly enhance durability and functionality. They provide stability, reduce friction, and prevent misalignment, making them indispensable for both residential and commercial applications. Investing in high-quality rollers ensures long-term performance and reliability.

Best Practices for Optimal Performance

For optimal performance, regularly clean and lubricate guide rollers to reduce friction and wear. Ensure proper alignment of tracks and rollers during installation. Use high-quality materials suited to the gate’s weight and usage. Follow manufacturer guidelines for installation and maintenance. Address misalignment or wear promptly to prevent further damage and ensure smooth gate operation over time.